Perception

Perception

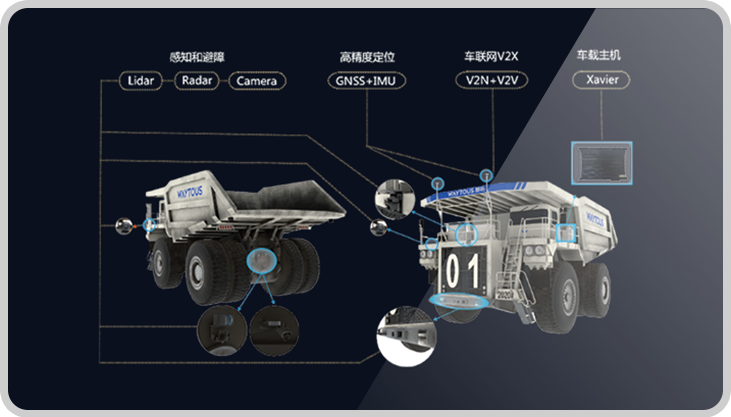

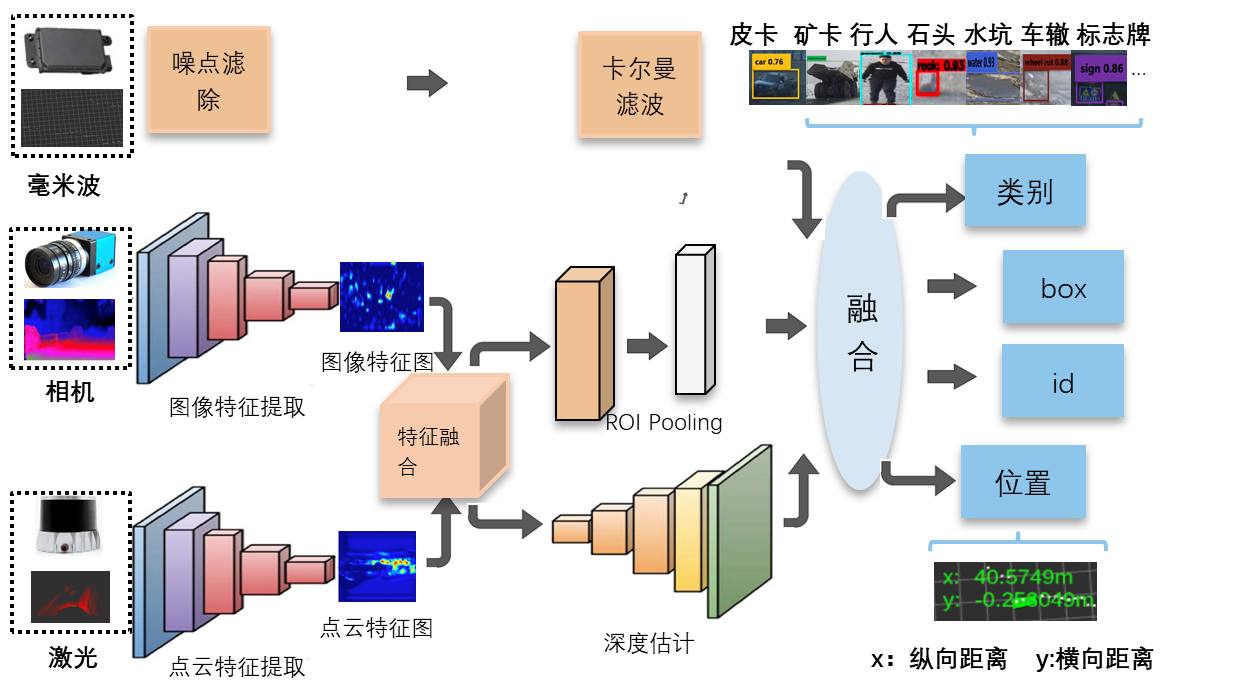

The preception system could work in harsh working conditions such as dusty, rainy, snowy, foggy, severe vibration, and extremely low temperatures in the mining area by fusing data from LiDARs, millimeter wave radars, and cameras, which could achieve high robustness in the detection and tracking of multiple targets during the bumpy driving.

Planning

Planning

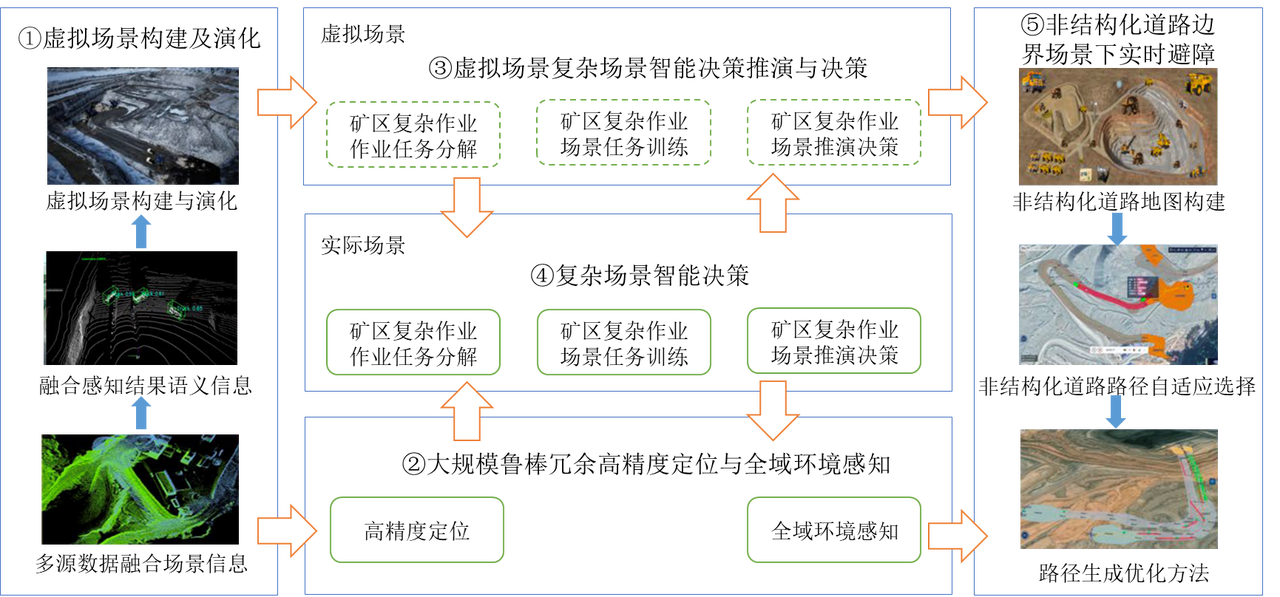

Autonomous mining trucks are equipped with intelligent decision-making and path-planning capabilities for complex scenarios, guiding the vehicle to complete missions safely, which can be applied to various extreme loading and unloading road conditions in actual production, ensuring high efficiency and safety in the production process.

Security Testing

Security Testing

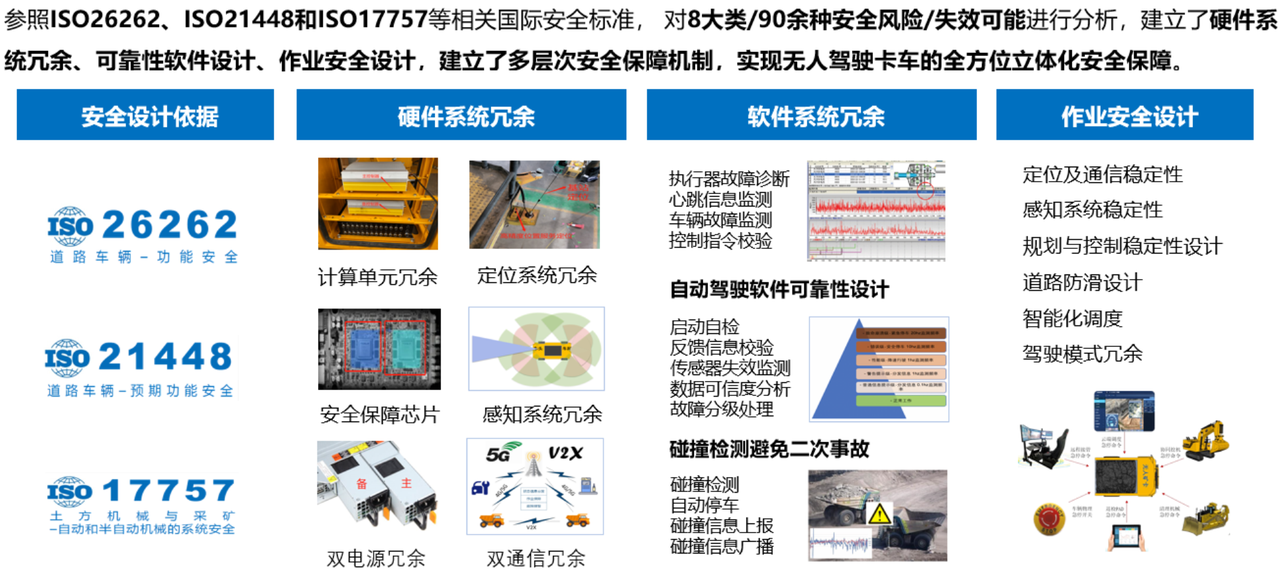

With reference to relevant international safety standards such as ISO26262, ISO21448 and ISO17757, the hardware system with redundancy, reliability software design and operational safety design have been established, and a multi-level safety guarantee mechanism has been set up to keep the autonomous mining trucks safe.

Combination localization

Combination localization

The multi-sensors fusion localization approach based on the mining areas has been developed by our technical team, which can realize the localization and posture estimation functions under the strong or weak GNSS signal environment, solving the problem of signal instability of GNSS system in the mining area (low responsiveness, easy to be obscured, long time signal loss in deep pits, etc.)

Mining Truck Control

Mining Truck Control

The original control algorithm following trajectories for autonomous mining trucks solves the impact of response differences from different mining trucks on control accuracy, achieving the highest operating speed and the smallest trajectory tracking error in this field, being able to control with full ranges and prevent slipping.

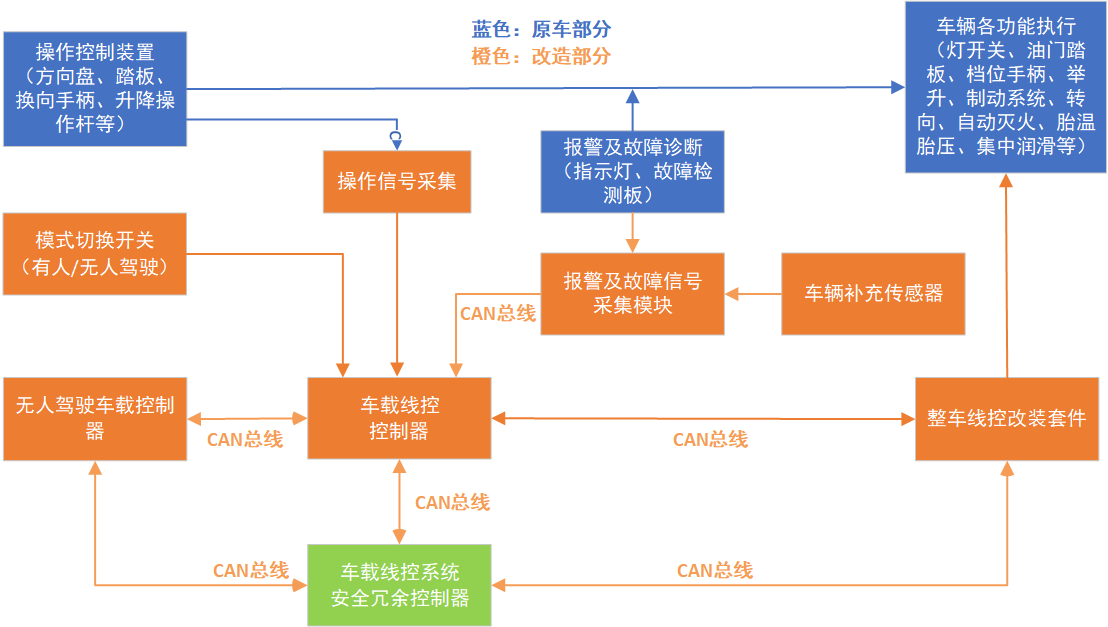

Wire Control System

Wire Control System

The experience of wire control transformation covers electric mining trucks, mechanical wheels mining trucks, articulated truck, electric wheels wide-body trucks, mechanical wheels wide-body trucks, etc. The truck brands include Xuzhou Heavy Industry, North Heavy Industry, Aerospace Heavy Industry, Komatsu Group, Volvo, Terex, Sany Heavy Industry, Yutong Bus, Lingong Group, Weichai Group, Tongli Group, etc., totaling more than 16 models, which can ensure the demand of driverless transformation for all models of trucks.

Data Collection and Update

Anti-rutting balanced crushing

Precise detection of non-standard retaining walls and adaptive parking

Bumpy road detection and automatic speed reduction

Steering delay adaptive precision control

System reliability and safety